Sugar cane cultivation in Brazil has existed since colonial times and was associated for many years with degrading working conditions, low productivity and high pollution, but it’s now one of the best examples of sustainable development in the region.

Brazil has the largest sugar-energy industry in the world, driving a long production chain. The sector plays a fundamental role in the economy, producing different forms of agro-energy, including sugar, ethanol, electricity and other products; and it’s also one of the best examples of sustainable development in the largest country in Latin America and the Caribbean.

According to 2019 data from the Ministry of Agriculture, Livestock and Supply, Brazil has 371 sugar-energy plants in the country, the majority (255) being of mixed production (sugar and ethanol). Currently, the sector represents around 2% of the country’s Gross Domestic Product. Sector estimates are for the 2022/2023 harvest to total 596.1 million tons, up 1.9% compared to the 2021/2022 harvest. The average productivity of the sugar cane fields in this harvest is estimated at 72.61 ton/ha.

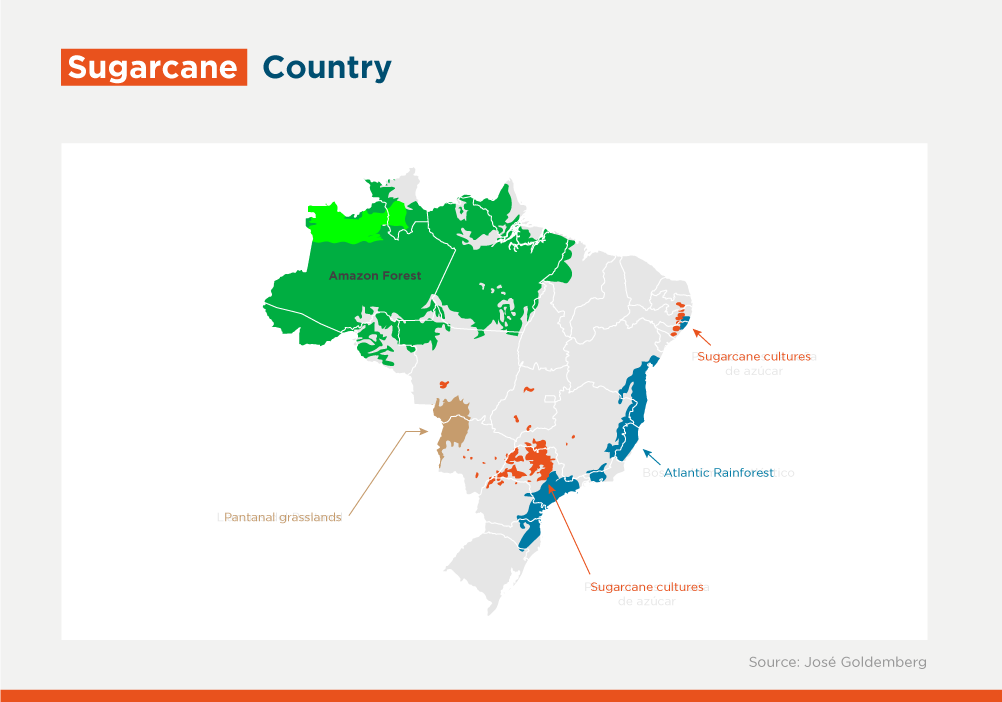

The production of sugarcane in Brazil is distributed throughout the country, but it’s most concentrated in the Southeast Region, which accounts for about 63% of national production.

This crop has existed since colonial times and was associated for many years with degrading working conditions, low productivity, high environmental pollution levels, water sources and air quality degradation, deforestation of protected areas and other environmental impacts. However, we are now witnessing a true revolution driven by professionalization, technological innovation and great advances in socio-environmental impact management and mitigation.

For starters, working conditions have changed significantly as a result of the sugarcane planting and harvesting mechanization. In the past, those tasks required large pools of unskilled labor, which were recruited both locally and far from the actual work sites. The recruiting agents’ influence was pervasive, making false promises and offering workers degrading working conditions. Worker accommodation was very poor, with inadequate living and sanitation conditions. At the end of the planting and harvesting season, temporary workers were massively dismissed, giving way to conflict and social tension.

Today, the planting and harvesting mechanization process has reduced or eliminated the demand for migrant workers. Most plants now demand full-time labor and invest in worker training, offering adequate legal, salary, health and safety, and job stability conditions. Although the total number of workers is smaller than in the previous model, the job quality has improved, training opportunities are offered, there is a marked decrease in demand for migrant labor, and the risks of slave-like working conditions and child labor have been drastically reduced.

To control remaining contracts with temporary workers, plants have invested in robust administrative systems that monitor suppliers’ legal and socio-environmental performance, including compliance with labor laws. The mechanization of the planting and harvesting stages will go a long way toward eliminating degrading forms of labor.

Another important topic is pollution reduction. In the past, sugarcane fields were burned during the harvest period to eliminate the straw, producing a large amount of smoke emissions and degrading the air quality over large areas. This practice was replaced with mechanized harvesting. By automatically cutting the cane and leaving part of the straw on the ground, this process contributes to organic matter recycling, erosion control and soil fertility preservation.

This activity, however, also generated large amounts of solid and liquid waste which was dumped with little control. Today, sugarcane milling and processing waste is fully utilized, to the point of being considered a by-product. Modern plants use these residues as fuel to produce energy. Approximately one third of the energy generated is used for plant operation, while the rest is sold to create an additional source of revenue for companies.

Another type of waste produced in large volumes is vinasse—a liquid rich in organic matter from ethanol production, which is used in the fertigation process to irrigate and fertilize crops. Filter cake is also an abundant residue, produced during the cane juice decantation process after crushing. Today, plants adopt a circular economy approach, whereby the waste that is not reused is adequately managed through solid waste management plans.

To reduce pesticide usage, plants implement advanced technologies, such as biological pest control techniques and herbicide microdosing equipment. The current production model avoids the deforestation of new areas through the environmental licensing of plantation areas.

Environmental licenses determine the areas that can be exploited and, if necessary, used for crop expansion. Most modern plants seek to expand production by extending land lease agreements and using technology that seeks to increase per-hectare productivity.

Better control of water resources is another quantum leap in terms of mitigating the climate change impacts. Most plants implement water reuse systems in their process, and crop irrigation is done through fixed and mobile systems that optimize water use. Using vinasse for fertigation also helps reduce crop water demands.

It should also be noted that most sugarcane mills produce ethanol, an important biofuel. From an entire fuel life-cycle standpoint, using ethanol in place of gasoline helps reduce greenhouse gas emissions drastically, while providing Brazil with credits that can be traded on the stock exchange.